Streamlining Production:relative Article

There are many examples to support the fact that wine filling machine makes a huge difference on the production level of wineries. Automated wine filling machines can process a minimum of 3,000 bottles per hour while traditional manual bottling processes cap at about 200 bottles per hour. Gardner says this dramatic rise in capacity is what enables a winery to fill orders the fastest and to adjust to market fluctuations.

Quality Control and Consistency

One of the biggest benefits of using an automatic filling system for bottling is that it helps to ensure consistency throughout. A wine filling machine delivers each bottle a precisely accurate fill, completely opposite from filled by hand, which is inconsistent in fill levels and spillage levels. This not only prevents waste from spills and overfills, but also guarantee that every bottle is of the highest quality standards that consumers demand. All this ensures brand reputation which is used to generate and maintain customer trust.

Reasonable in the Long Term

It requires a substantial amount as initial investment for wine filling machine but it also helps in cost-effective in the long run. The number of staff needed to manage these machines is generally fewer, which in-turn greatly cuts labor costs. What is more, the decrease in waste and processing time allows wineries to expect that their investment will pay for itself in 2-4 years, dependent on the size of the operations.

Enhanced Worker Safety

Automating the filling process requires less human involvement with the machines, significantly reducing the risks of accidents at work. Repetitive heavy lifting, especially lifting bottles: Manual bottling processes require efficient workers with repetitive motions and the handling of heavy containers - both of these can lead to musculoskeletal injuries. Automate the most dangerous and strenuous jobs with wine filling machines and maintain the safety of the workplace.

Flexibility and Scalability

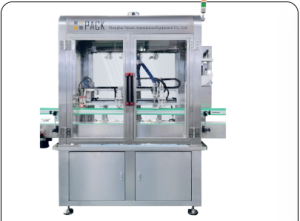

Today's wine bottling machines are made to be adjusted to many range of bottle formats and sizes, from the 750 ml standard bottle to the bigger formats. This flexibility means that instead of needing add additional equipment, wineries can still diversify their product offerings. Also, as the business grows, these machines can be scaled sometimes even upgraded to cater increased production demands without having to overhaul the production line entirely.

Sustainability Considerations

As the world moves toward more sustainable practices, wine filling machines offer a greener choice to bottling as usual. Compared to other traditional wine-making methods (aging wine in barrels) they are more energy-efficient and minimize waste production --a must for the sustainability goals of many wineries today-- so are an ideal choice for anyone making small batches of spirits. Alternatively, it could be a selling point with green consumers - competitive advantage.

Looking Forward

Solution 1: 5 Benefits Of Investing In A Wine Filling Machine It can be a competitive and costly market out there invest in a wine filling machine can have a significant impact on a winery with your cost-effective solutions and years to come competitiveness. Bottling automation is the future for wineries looking for a guarantee of quality, safety, and sustainable production in addition to a long-term investment strategy for their winery businesses.